When Paul Pumputis, Western Regional Manager at Duffy’s Equipment Service, Rochester, N.Y., received a call from a customer concerning issues with a new combi, he experienced just how frustrating it can be when people simply won’t listen.

“The customer, at a school that was recently renovated, told me they heard a loud pop when a burner inside of the combi cooking chamber fired up,” Pumputis explains. This particular unit had three burners, two in the cooking chamber and one in the boiler. “When the operator turned the combi to full steam mode, the unit’s gas pressure dropped to less than half of the manufacturer’s recommended amount,” Pumputis explains. “However, when that burner was off, the machine maintained the ideal amount of gas pressure.” This led him to consider that the problem was the gas line supplying the equipment, rather than the equipment itself. “It was clear to me that we had a supply pressure issue, not an equipment failure,” says Pumputis. He recommended the customer contact the gas company to check the line and make the proper repair.

“After I left, the customer instead called the dealer, the manufacturers’ rep, the renovation construction supervisor—anybody who had a phone number,” Pumputis jokes. The contractors who had renovated the kitchen and installed the equipment insisted that there couldn’t possibly be anything wrong with the gas supply. The gas company, too, verified that the pressure entering the building was adequate. The customer let Pumputis know. “I told him I’d be happy to come out and explain the situation to whoever is telling you the supply is OK,” he says. He returned to meet with the dealer and the school’s foodservice director and showed them the pressure drop on his monometer that occurred in full steam mode.

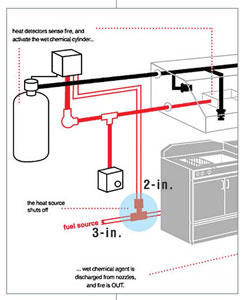

A few days later, the customer called and asked Pumputis to meet again, this time with the dealer, the manufacturers’ rep, and an engineer from the gas company. While the dealer and rep checked the combi, Pumputis followed the lengthy gas line with the gas company rep. “This was the most gas-demanding piece of equipment on the line, and the designer had placed it at the farthest end from the gas supply. It required a 3-in. gas line to deliver enough gas over this distance, which it had.” As he reached the end of the line, he finally found the culprit. “Even though the gas line itself was large enough going into the building and coming down the line, when it ‘T’d off to the cookline’s fire suppression system, the diameter of the line was briefly reduced down to 2-in.—creating a gas bottleneck that was only a problem when the combi was pulling gas for all three burners,” Pumputis explains. Boosting pressure to the site compensated for the fault and all was fixed. Pumputis now advises his technicians, “when you’re right and you know you’re right, it’s OK to push.”

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -