SPONSORED CONTENT

Cold storage plays a critical role in the success of any foodservice operation. The walk-in cooler or freezer directly affects product safety and quality and is essential for minimizing food spoilage and overhead costs. Choosing a walk-in with premium insulation, best-in-class construction, and an eco-friendly refrigeration system significantly contributes to your bottom line.

Walk-ins are highly customizable and can be outfitted to meet specific needs. Some operations only need a cooler that keeps products at +35°F and are ideal for quickly perishable items or products that need to be offloaded promptly. Some need a freezer, which keeps products around -10°F, and are ideal for preserving products for extended periods. Some opt for a cooler/freezer combination to get the best out of both worlds. It all depends on individual needs.

Configuring a unit can feel overwhelming at first. Here, we outline the key considerations to help make this process as smooth as possible.

Location

Is the walk-in going to be installed inside or outside? Wherever it goes, the location will require adequate airflow and ventilation, and utility access for electrical wiring, drainage, and refrigeration lines.

While not every layout is accommodating, indoor walk-ins allow staff quick access without exposure to outdoor elements and a closer proximity to the kitchen. Indoor environments are also more controlled than the outdoors, so there’s less risk of vandalism, and it establishes consistent operating conditions that reduce the strain on the refrigeration system.

An outdoor walk-in offers greater location flexibility and can create a more comfortable work environment inside, as indoor units can sometimes be loud and cause heat buildup.

Learn more about location considerations.

Size and Storage

The size of the walk-in will depend on the types of items and how much storage is needed. Plan for proper shelving to maximize the vertical store space, as well as sufficient aisle space for easy access to products.

Standard sizes range from 6’6 to 10’x14’, but because needs vary greatly, Norlake can design in-house whatever size or cooler/freezer combo that is needed.

Common sizes include:

- 6’6’ or 8’8’ – ideal for small restaurants

- 10’x10’ or 12’x12’ – ideal for mid-sized operations

- 20’x20’ or greater – ideal for large facilities or warehouses

More about size and storage considerations.

Floors

Walk-ins can come with or without built-in floors. Walk-ins with floors offer a host of benefits, including:

- Better insulation

- Easier installation

- Prevents moisture issues

Units without a floor need to be installed on a level concrete surface, and additional steps may be needed to ensure proper efficiency. Most floors are constructed with smooth aluminum and are designed for light to medium-duty traffic. Heavy traffic, like lifts or carts, requires a heavy-duty floor to avoid floor panel damage.

Panel Construction and Insulation

The construction of the walk-in panel is a significant factor in the unit’s structural integrity, energy efficiency, and longevity. The panel material varies across manufacturers, but Norlake’s standard is acrylic-coated galvanized steel that offers many benefits, including:

- Corrosion resistance

- Highly durable

- Cost-effective and low maintenance

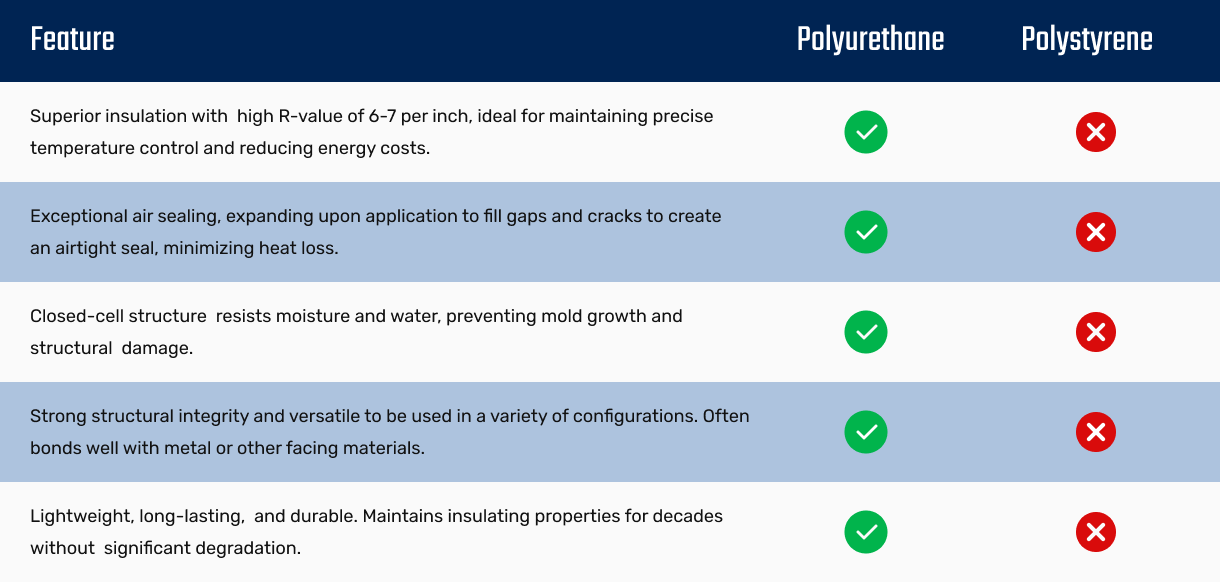

The walls of the panels are then filled with insulation. The most common insulation materials are polyurethane, a rigid and closed-cell foam with a high thermal resistance, and polystyrene, a lightweight and cost-effective foam ideal for budget-friendly operations.

More on panels and insulation.

Refrigeration Systems

The refrigeration system type will depend on the application and location of the unit. The two categories are self-contained, where all the components, like the condenser and evaporator, are housed within the unit, and remote, where the condenser and evaporator are housed separately.

Self-contained systems are ideal for small to mid-sized foodservice operations. Benefits include:

- Compact, space-saving design

- Easy installation

- Simplified service

- Lower upfront and maintenance costs

Remote systems are best for larger operations. Benefits include:

- More customizable

- Reduced heat and noise

- Greater cooling capacity and energy efficiency

More on refrigeration systems.

Controls

The walk-in’s controller system ensures internal temperatures remain within safe ranges while reducing energy consumption. These control the fan speeds based on cooling demand, alerts, and the defrost cycle that’s necessary to prevent ice buildup.

Many electronic control systems also enable operators to have complete control on the go from their smartphones or tablets and provide troubleshooting tips and actionable insights. Norlake’s LogiTemp® Plus with Reverse Cycle Defrost control system completely defrosts coils in under 5 minutes and saves operators up to 27% more energy compared to all-mechanical controls.

Many electronic control systems also enable operators to have complete control on the go from their smartphones or tablets and provide troubleshooting tips and actionable insights. Norlake’s LogiTemp® Plus with Reverse Cycle Defrost control system completely defrosts coils in under 5 minutes and saves operators up to 27% more energy compared to all-mechanical controls.

Norlake is the trusted partner of choice in cold storage solutions, offering the industry’s best standard walk-in warranty to ensure every operator can feel confident in their purchase. Norlake’s walk-ins are completely customizable to meet specific demands, and availabled with patented, environmentally-friendly R-290 refrigeration systems manufactured in-house, future-proofing against supply chain shortages and regulatory changes.

About Norlake: Lower the temp and raise the bar with Norlake, the trusted partner of choice in cold storage solutions. We offer unmatched scale, unbeatable quality, and an unrivaled legacy spanning 150+ years of engineering excellence. With two strategically located facilities and in-house refrigeration design and manufacturing, we deliver proven success, efficient design, end-to-end support, and a commitment to quality. Backed by the industry’s best standard walk-in warranty, worry-free installation and commissioning, and the largest service network, we’re always ready for what’s next.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -