Survival Guide: Water Filtration Systems

There’s no food prep, drinking, cooking or cleanup without water. Your customers drink it, it powers your combis and steamers, and it cleans and sanitizes your dishware, glassware, utensils, pots and pans.

"Water” seems like a transparent concept, but the flow is never just H2O. The liquid also contains minerals like calcium and magnesium (the amount determines the “hardness” of the water), chemicals such as chlorine and chloramines (a chlorine-ammonia compound) added for purification, and suspended solids and sediment. Many of these are problematic in foodservices, and getting rid of them means filtration.

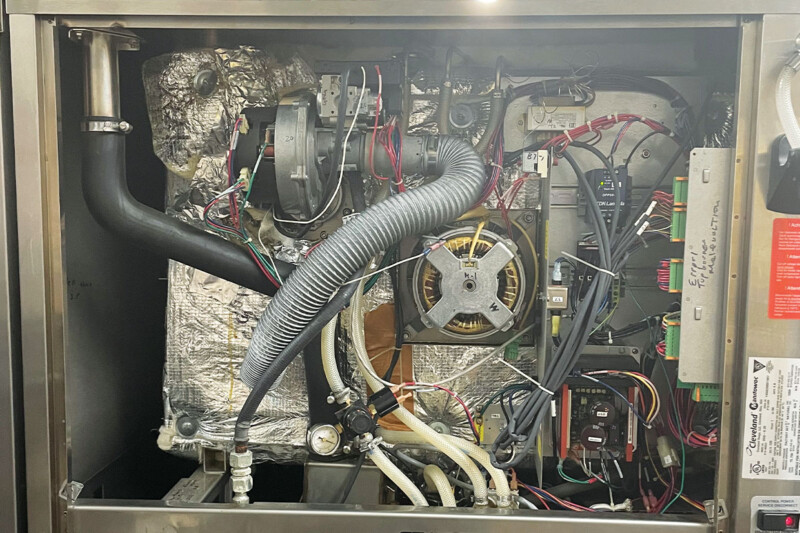

Different uses of water require different filtration technologies. For espresso and coffee, the Specialty Coffee Association of America details specs for water hardness and total dissolved solids, and mandates a near-absence of chlorine and chloramines. For post-mix soda machines, the goal is removal of sediment as well as chlorine and chloramines; beverage companies have their own specs. Combis and steamers are very sensitive to the calcium or magnesium in hard water as well as to chloramines. In ice machines, water should be as clean as possible with no sediment that could harm the machines’ pumps or seals. For warewashers, it’s important to remove minerals that could cause scale in the machines and spots on glassware. Filter tap water to remove chlorine or chloramines, sediment and other contaminants such as bacteria or parasites.

A tremendous difference in the composition of city water from one area to another also complicates selecting filter systems. To find out what’s in yours, inquire at your local water district. Or, better yet, work with the manufacturer of your filtration system; some companies offer a test kit that you can mail back for analysis.

The system that was the right choice a few years ago may not be right today. In the past few years, many municipalities have switched from chlorine to chloramines as a safer and more effective disinfectant. (Some use chloramines only part of the year.) Chloramines can affect the taste of water and can corrode steam equipment and weaken seals, but it’s harder to remove from water than chlorine, and requires a special carbon filter.

Other big news in water filtration is suppliers’ development of more-efficient reverse osmosis systems, in which water drips through a fine membrane that catches impurities. Older systems were slow and wasted water, but dramatically improved technology means RO filtration is now in more widespread use.

In short, it’s complicated. Consult with an expert to choose the right filtration system for each of your operation’s needs.

Why Maintenance Is Essential

No filtration system will solve your water issues for long without proper maintenance. Without it, you’ll eventually run into any number of problems, from off tastes in ice, water, coffee or fountain drinks to low water pressure, equipment downtime and unplanned service calls to shortened equipment life as a result of corrosion. In other words, higher input costs, reduced sales or both.

Filter Switch Ritual

Maintenance of a water filtration system mostly comes down to three words: change your filter! Use your computer email calendar, cell phone reminders or a good old calendar hanging on the wall and schedule reminders.

• How do manufacturers help keep restaurants on track? Some suppliers automatically ship new filters to units when switch-outs are due; others send the restaurant email or phone-text reminders. The advent of the Internet of Things now allows for real-time monitoring of filtration systems. One manufacturer’s onboard monitoring measures how much water has gone through the system and sends an alert when the filter has reached 80% capacity and again when it reaches 100% capacity. A filter-change transmits via WiFi to an app on the operator’s or servicer’s smartphone.

• Who changes the filters? In most cases, unit staff can do the job. Some restaurants have contracts with servicers for routine filtration system maintenance such as filter changes; some chains have their own maintenance staff visiting units to make switch-outs on schedule. RO filtration systems are more complicated, so specialists usually maintain them.

• What does a filter change involve? Shut off the water supply to the system, remove and dispose of used cartridges, remove new cartridges from their packaging, insert new cartridges, turn the water back on and flush the system for five to 10 minutes or as directed. Most cartridges today are easy to remove—slide them out with a simple quarter-twist; reverse the motion to install the new filter. Write the date on the newly installed filter or in a log book.

• When should filters be changed? Change filters on a regular schedule. Follow the manufacturer’s recommendation. For older systems, filters needed replacing about every six months, but many modern, large-capacity systems require only an annual filter change. Change sediment pre-filters quarterly.

Monitor your water filtration systems for evidence of sub-performance. Change filters if they become clogged or the water flow or water pressure drop substantially, even if it isn’t yet time for the scheduled replacement. Check the pressure gauge; incoming water pressure should be at least 35-40 psi, and ideally 60-70 psi for maximum performance.

Periodic analysis of water quality is another good idea. “Most end-users think that as long as water is coming out of the filtration system, it must be OK,” one expert notes. “That’s not true. Filters have a lifespan capacity. In an area where you don’t have a lot of suspended solids to plug up the filter, the fact that you have apparently clean water coming out can give you a false sense of security.”

What Else To Know?

In addition to periodically checking for reduced water flow or pressure, keep an eye out for water leaks, unusual discoloration of water or a buildup of pre-filter or post-filter residue on components. Monitor water-using equipment for corrosion or scale buildup.

Even if you regularly maintain your filtration system, you can’t expect it to last forever. Manufacturers typically offer a five-year warranty, although systems can last longer. Major changes that might make it advantageous to upgrade to a new system before the old one gives out include:

• Changes in your menu or the number of covers per day.

• Installation of new water-using equipment.

• Changes in your municipal water supply.

• An advance in filtration technology that could benefit you.

Take good care to regularly maintain your water filtration system and customers will better enjoy beverages and your equipment will run more efficiently and last longer.

Water Filtration System Specialists

3M

mmm.com

Antunes

antunes.com

Aquasana Inc.

aquasana.com

Ecolab

ecolab.com

Everpure/Pentair

everpure.pentair.com

Selecto Inc.

selectoinc.com

OptiPure

optipure.com

Many companies supply water filtration systems, including manufacturers of equipment that uses water. For a more complete listing, visit the FER Buyers Guide at fermag.com.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -