Coffee Brewer Do’s, Don’ts

Daily cleaning and regular filter changes make a difference with high-volume coffee brewers.

Americans are drinking more coffee than ever, according to the National Coffee Association’s 2020 survey. Consumption is up 5% in five years, and the average American coffee drinker consumes more than three cups per day. To meet the demands of today’s caffeine fanatics, it’s critical your high-volume coffee brewer is in tiptop shape. Maintaining your high-volume coffee brewer ultimately ensures a fresh, tasty product in the short-term and cost savings in the long-term.

Follow these do’s and don’ts when it comes to maintaining high-volume coffee brewers.

DO TRAIN YOUR EMPLOYEES. Training and informing staff on proper maintenance protocols is the first step in getting the most use out of the equipment and keeping repair costs down. Explain what must be done daily, weekly, monthly and yearly, setting a specific schedule if necessary. Enlist a service technician to show your team proper cleaning techniques and educate them on why such maintenance is important.

DON’T FORGET TO DO DAILY CLEANINGS. One of the biggest mistakes service agents find is daily cleaning neglect.

“[Coffee] leaves behind a film or residue that becomes thick and sticky if not cleaned regularly,” says EMR Co. Salisbury Technician Greg Meleney. “This buildup can eventually clog spray heads and, in some cases, dispense lines, which adversely affects the product quality.”

Gary’s East Coast Service Technician Donna D’Aquino recommends employees rinse the brewing pots, wipe the brew heads and clean the spray head. TWC Services Senior Beverage Technician Steven Lokey adds: “The best thing the customer can do is remove the spray head and clean them every week. There’s no need to soak it in a cleaner as it’s quicker to wipe it off. If it’s clogged, use a pointed instrument such as … a spray head cleaner tool … to ensure it will flow the proper amount of water to the coffee grounds.”

It’s also important to note: Operators should not clean brewers with vinegar. One of Lokey’s customers had been pouring up to two gallons of vinegar into the manual fill and letting the machine run clean before using it. In such a case, Lokey had to take the entire machine apart and clean the buildup left by the vinegar.

DO CREATE A PLANNED MAINTENANCE SCHEDULE. In addition to daily cleanings, it’s important to schedule technician service. Lokey says planned maintenance can catch small issues before they become more costly and time-consuming.

“Depending on the volume of business the customer has, planned maintenance can be done monthly, every six months or even yearly if the store volume is low,” Meleney says. “Check the consumption rate of the water filter and base your planned maintenance around that.”

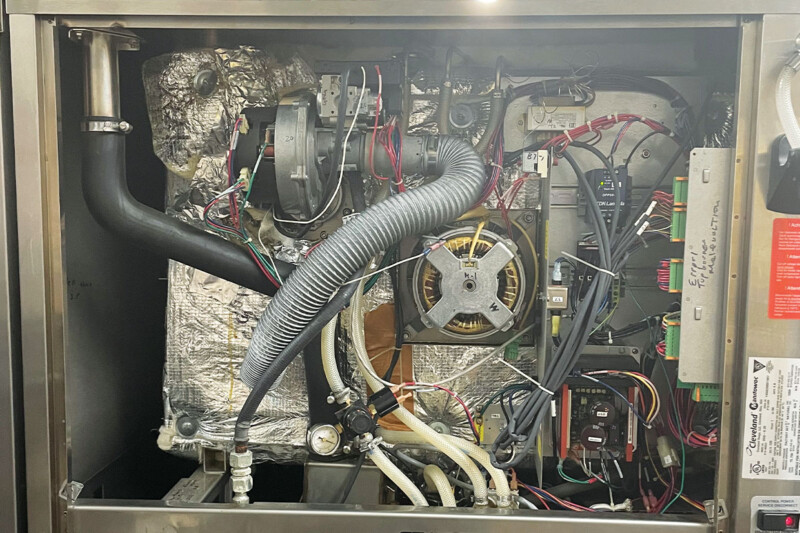

During planned maintenance, the technician will change the water filter and remove the brewer from service for a short period of time. Then, Lokey says the service agent will “delime the unit by taking the hot water tank out and giving it a few knocks. Most of the scale will come out, but the harder buildup will need to be removed by hand, tools and/or chemicals.” Once completed, the technician will inspect the brewer for brittle silicone fittings and hoses.

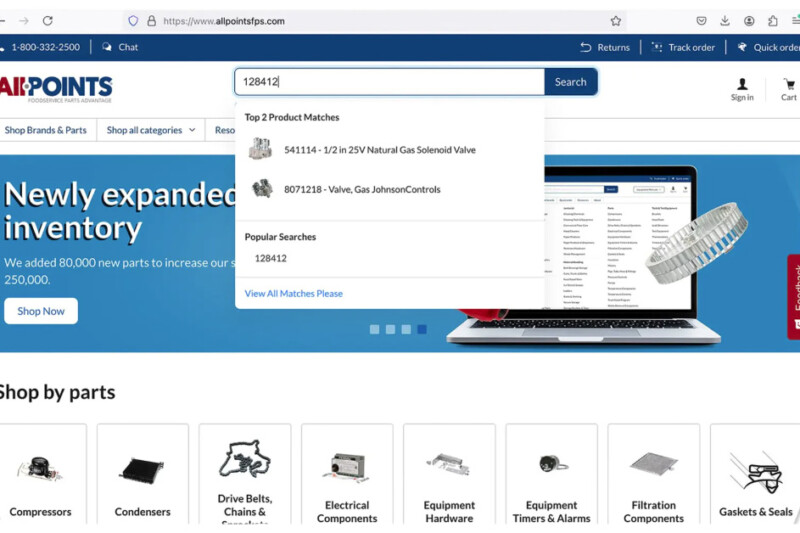

DON’T UNDERESTIMATE FILTER CHANGE NEEDS. Lokey, Meleney and D’Aquino agree that operators don’t change the water filters enough.

“The quality of the water supplied to the machine needs to be maintained with water filters,” Meleney says. “Improving the quality of the water will help reduce scale buildup, which can clog drains and valves. It can also insulate elements and probes, causing service issues.”

D’Aquino says neglecting to change the filters can lead to brew issues in volume and quality, and it can even lead to leaking, which, in turn, causes rotting. Once the high-volume brewer begins to rot, there’s a high chance the operator will have to invest in a new system.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -