Selecting Pizza Pans? Here’s What You Need To Know

With so many varieties of pizza pans, here's how to select the one that will provide the optimal bake.

Everyone’s got a favorite pizza—be it crispy thin crust, hand-tossed New York style, deep-dish Chicago or newly popular varieties like Detroit-style pizza. Given all the varieties of pizza, it only makes sense that there are myriad pizza pan choices. Some manufacturers customize, offering over 3,000 varieties.

Start your selection process by specifying what you want. In addition to size, consider the type of crust desired, cooking-time requirements, durability of the pan, time-saving features, like pre-seasoned coatings, and space-savers, such as nesting pans.

Hard coat anodized aluminum pans have a dark surface that absorbs heat for faster baking times. Courtesy of Lloyd Pans.

Get the Hole Story

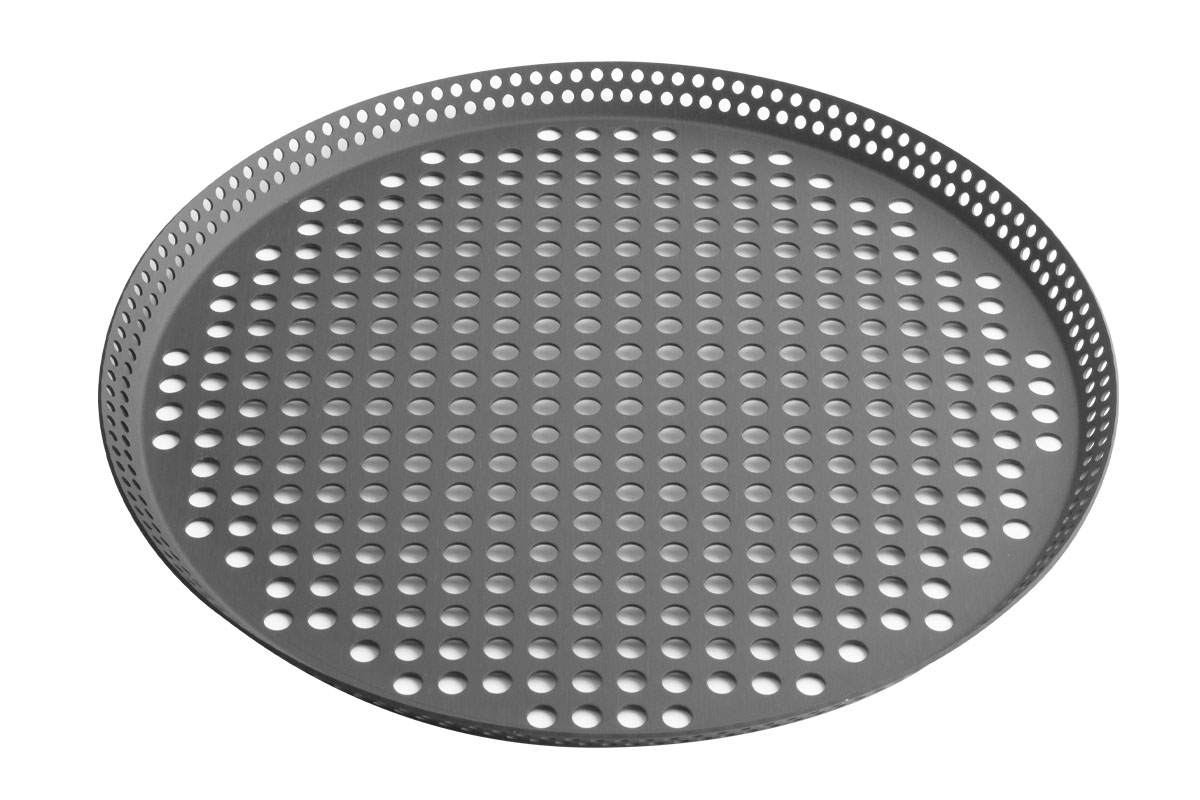

One major choice is perforated versus solid pans. A solid pan bakes up a doughier, chewy crust—generally the right match for pan pizza and sometimes for hand-tossed, depending on your dough formulation and preferences. Perforated pans allow for more airflow, resulting in a crisp crust. In general, the more perforations, the crispier the crust.

Select the number and size of perforations to achieve your desired results. One manufacturer offers hexagonal perforations, which allow the holes to be positioned closely, permitting 50% airflow. Another makes a fully perforated pan, with holes on the sidewalls to increase airflow.

Flat, perforated disks are popular with operators striving for crisp thin-crust pizza. Without any sidewalls, disks allow for increased air circulation. Similarly, some operators use a flat, mesh pizza screen. When comparing prices between disks and screens, consider the product’s longevity. The less expensive screen is difficult to clean and easy to warp. It may last only a few months, while a pizza disk may last up to 10 years. Mesh screens are generally not NSF certified.

Perforations allow moisture to escape easily, speeding up the cooking process and helping the pizza cook evenly. Saving a couple minutes per pizza can substantially increase your throughput, especially important when feeding time-pressed customers during the lunch rush or serving pizza in a concession setting, like a stadium.

Perforated pans, disks and screens are a good match for a conveyor oven, which quickly crank out high volume. They’re not as suited for deck ovens, where there’s no airflow below the pan to allow moisture release.

Beware of perforations if you pre-prep pans with dough. The dough might sag through the holes when sitting for hours in your walk-in. Consider a solid pan or one with smaller holes.

Think Outside the Circle

While round pies remain the industry’s mainstay, pizza operators are branching out to satisfy Americans’ appetite for variety. Long a regional favorite, Detroit-style pizza has gained popularity nationwide in the past decade. The rectangular, deep-dish pizza features toppings that extend to the perimeter, forming outer edges of caramelized cheese. The specialty pizza emerged in the Motor City back in the late 1940s, when the originators used rectangular, blue steel automotive parts pans to bake their pizza. Since driving into the national spotlight as a winner at the 2012 International Pizza Expo, Detroit-style pizza has gained traction. In turn, manufacturers have revved up production of these pans.

Square-shaped, thick-crusted Sicilian pizza also has seen an upsurge in demand. In response, manufacturers have rolled out pans to bake this specialty pizza, long popular in New York City. Other rectangular pans abound, including those for grandma-style pizza—similar to Sicilian but not as thick—and Roman-style al taglio pizza, which features an airy, yet crispy crust. One manufacturer recently introduced a line of deep-dish long pans. The narrow, rectangular pans are 4 inches wide and up to 27 inches long. Elongated pans are perfect for baking Sicilian and Detroit-style recipes in a format that lends itself to sharing at a bar or long table.

A tandem pan increases throughput. Courtesy of Chicago Metallic.

Finish Strong

Aluminum is commonly used for pizza pans because it’s an efficient conductor of heat. Many manufacturers offer an upgrade to hard coat anodized aluminum, in which the metal has undergone an electrochemical process that strengthens it, provides corrosion-resistance and adds a hard, dark finish. The dark surface absorbs heat, allowing for even, thorough cooking and faster baking times. At least one manufacturer offers a clear coat anodized finish. This less expensive option is not as durable as hard coat, but stronger than raw aluminum and still helps protect from corrosion caused by acidic foods.

Anodized aluminum has a porous surface, creating a sticky situation, literally. Operators must season the pans before use to prevent the crust from sticking. The seasoning process, which requires oiling and heating the pan a few times, fills in the pores and creates a stick-resistant barrier.

Some manufacturers offer pre-seasoned hard coat anodized pans that reduce labor and oil costs associated with seasoning. These baked-on finishes allow for easy release of the pizza. Examine your return on investment to determine if it’s worth the extra upfront cost for your operation. At least one manufacturer offers a premium coating allowing easier release for gluten-free pizza, where dough can be sticky and crusts flaky. The pan’s purple finish differentiates it from other pans and helps prevent cross contamination.

Consider the gauge, or thickness, of the metal. The higher the gauge, the thinner the pan. In general, a thicker pan offers more durability and longevity. Still, some operators like the bake they get from a thinner pan. Aluminum pans are typically available in 14 to 20 gauge. Other popular materials include aluminized steel and tin-plated steel, both thinner than aluminum pans, but with the strength of steel.

Perforated pans versus solid pans, allow for more airflow and so produce crispier crust. Courtesy of Vollrath.

Sample a Selection

With so many choices, some operators feel like a wide-eyed guest at a pizza buffet—and similarly sample a few. Test bake to determine which pan operates best with your recipes and in your oven. For efficiency’s sake, operators commonly leave oven temperatures constant for a variety of menu items, so see what works given your settings. Get ready to sink your teeth into the selection process.

Ready, Set, Bake

Start your pizza pan research by reviewing the following hard coat anodized aluminum models from four suppliers.

Vollrath

Model: Fully Perforated Press Cut Pizza Pans

Features: Perforated pans allow for maximum airflow, leading to shorter baking times and crispier crusts compared with solid pans.

Website: vollrathfoodservice.com

Lloyd Pans

Model: Detroit-Style Pizza Pans

Features: The dark finish on these pans bakes hotter and faster than bare aluminum; sides angle at 76° for nested storage.

Website: lloydpans.com

Chicago Metallic

Model: Exact Stack Pizza Pans

Features: Easily stack these pizza pans with dough inside without the use of lids or separators, reducing equipment costs and saving space in storage and prep areas.

Website: cmbakeware.com

American Metalcraft

Model: Hard Coat Detroit-Style Pizza Pans

Features: Pans measure extra-deep, ranging 2⅜ , 2½ or 2¾ inches; pan lids and a flexible server are available.

Website: amnow.com

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -