A popular restaurant destination for wings in Toledo, Ohio, opened as a retrofit of an existing location. It had been in business less than a year when the manager called Jesse Dobbelaere, the Bowling Green, Ohio-based Regional Manager for CaptiveAire, with a problem. The restaurant’s hoods weren’t capturing smoke and grease, and the restaurant’s service provider suggested the operator call in a ventilation expert.

The restaurant’s design featured oversized, wooden entry doors “about 8-ft. tall with glass windows, wide frames and giant metal hinges,” Dobbelaere recalls. “I had to use both hands to pull the door open and go inside.” While he was waiting for the manager, he actually saw one potential customer try the door, then turn away and leave. “She must have thought the door was locked—it was that hard to open,” he says.

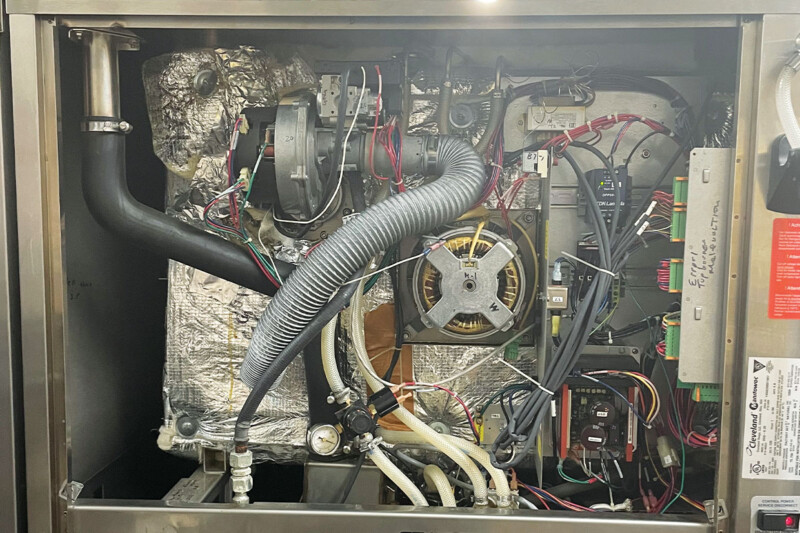

Once in the kitchen, Dobbelaere quickly spotted the cause of the ventilation problem. The cookline was covered by a 20-ft.-long, short-circuit hood. Short-circuit hoods operate by introducing outdoor makeup air directly into the canopy rather than allowing the hood to draw makeup air gently from plenum and/or vent supplies in the surrounding space outside of the hood. What happens is that the stream of makeup air causes turbulence and actually blocks the plume from exhausting from the cookline. Unable to exit the ductwork, smoke rolls out into the kitchen.

Adding insult to injury, the short-circuit hood also blew outside air down on the cooks. Chilled by the stream of winter air, they had turned off the makeup-air supply fan altogether. “The building was about 2,500 cfm short on air-pressure balance,” Dobbelaere says. In other words, the hood was sucking out more air than was coming in. With no makeup air, the restaurant experienced negative pressure, pulling doors shut and rolling smoke and grease into the kitchen and dining room. Other side effects included cross drafts—when someone succeeded in getting a door open—brown, greasy ceiling tiles and a perpetual haze and odor.

A negative air balance in a restaurant impacts more than just air quality and doors. Dobbelaere checked the hot-water tank. “Restaurants tend to have their hot-water tank in or near the kitchen,” Dobbelaere says. “Most tanks rely on a natural draft heat rising—to carry the gases up and out through the flue. But when the building is starved for air and in a negative-pressure situation, it will try to pull in air from any opening, including the water tank’s flue pipe. The backward airflow can trap combustion gasses in the tank. In a worst-case scenario, the downdraft can blow the flame in the wrong direction and lead to a fire.”

For the owner, replacing the hood was too expensive. The workaround involved installing a new makeup-air unit that delivered tempered air through a ceiling plenum near the hood. Workers then sealed louvers and internal vents inside the hood to block outside air from the old system. Short-circuit hoods are outdated and should be replaced or fixed immediately.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -