Florida’s Morgan High School Equips For Coming Population Boom

At the newly built school in Wimauma, Fla., a walk-up window-style servery is dishing out lots of lunches.

When Hillsborough County Public School leaders began planning the county’s newest high school back in 2020, one goal was a given: Think big. Opened in August 2025 in the Tampa suburb of Wimauma, Fla., Aquilla J. Morgan High School met that goal and then some. Built at a cost of $178 million, the school covers 360,000 square feet. Enrollment on day one tallied about 1,500 students; in a few years, the school will reach capacity at 3,500 students.

Growth defines Morgan High School. Wimauma’s population, currently just under 14,000, has doubled since 2007, and is continuing to boom. Thousands of new homes are already approved for construction in south Hillsborough County, according to local media reports, and Morgan sits right in the heart of that expansion.

The “Home of the Mustangs” stands as both HCPS’s largest school and its most cutting edge. “We tailored the school to have a community-centric campus, (surrounding) the dining area and courtyard with state-of-the-art facilities and classroom spaces,” says Frank Sepcic, principal of St. Petersburg, Fla.-based PBK Architects, the firm behind the school’s overall design. The three-story-tall structure includes a collaborative media center, a two-story gym with walking track, a game design room, culinary lab and cosmetology program, along with safety features such as remote access doors and marked shelter zones. The school also will serve as an evacuation center in the event of a hurricane.

Staff members prewrap burgers and sandwiches to speed service. Photo courtesy of Matt Andrus, TBCI Design

Lotsa Lunches

Cutting edge extends to Morgan’s dining services as well. HCPS’s lunch menu, shared across all the county’s high schools, spotlights teen favorites, including cheeseburgers, crispy chicken sandwiches, pizza and calzones, as well as more fruit/veggie-forward options such as chef salads, watermelon with tajin and burrito bowls. To execute this menu at Morgan, HCPS leaders requested an efficient walk-up window-style servery.

The challenge lay in fine-tuning the equipment and layout to “maximize throughput and flexibility across Morgan’s 50-minute lunch periods,” says David Hammersley, principal at foodservice consulting firm TBCI Design, St. Petersburg, Fla., who together with VP of Design Ashley Walogorsky, collaborated on plans for the servery, kitchen, culinary lab and concessions. When enrollment more than doubles to reach capacity in a few years, the servery must be capable of feeding about 1,000 kids per hour across three hours.

Servers assemble meal components (with key items prewrapped for speed) onto cardboard trays. Photo courtesy of Matt Andrus, TBCI Design

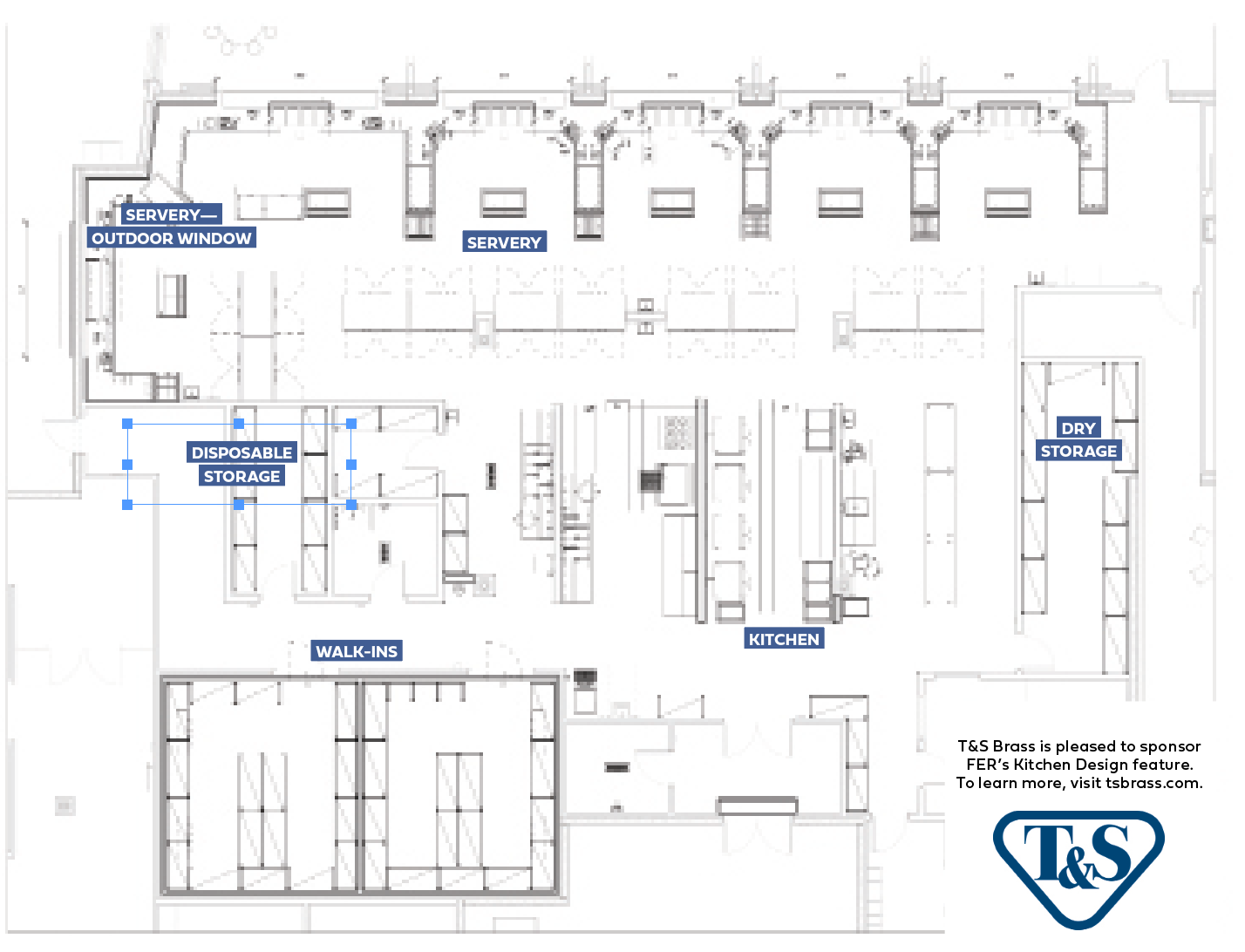

Bay Watch

Morgan’s servery consists of six 200-square-foot serving bays fronted with 12-foot-wide windows. Each bay holds two stations for a total of 12 points of service. Five of the windows face out into the 12,500-square-foot hall, where long tables provide seating for 900. The sixth window faces the outdoor courtyard, with an additional 240 seats. At lunch periods, students line up on either side of the hall, waiting to be dispatched to a designated serving lane by lunch supervisors to ensure lines stay roughly even.

Two months into operations, “For our two lunch periods, we’re serving about 560 meals in 30 minutes, giving students 20 minutes to eat,” says Morgan Student Nutrition Manager Ashley Dorsey. “The wait time per person is about 10 minutes, compared to an up to 20-minute wait time at nearby high schools.”

In each bay, flat-screen monitors hang from the ceiling, displaying the daily menu as well as school nutrition messages. In the center of the counter, strategically placed in front of student customers, a set of four food wells with hot, cold or frozen capabilities spotlight select items. Servers assemble meal components (with hot items prewrapped for speed) onto cardboard trays.

Directly behind the cashier/servers, a well-lit display case holds colorful bottled beverages and prepackaged sandwiches and salads. An open-shelf hot display cabinet (easy to restock), one for each station, puts prewrapped hot items in easy reach. A clear-topped freezer holding novelty frozen treats (“a must in the Florida heat,” Hammersley notes) rounds out each station’s equipment lineup. All the freestanding units sit on wheels for ease of repositioning and cleaning. The farthest left bay, in the corner, includes enough extra space for a prep table holding extra supplies next to the drinks display case. Completing the servery, a line of full-height pass-thru hot and cold cabinets, one pair backing each bay, separates the servery from the kitchen both visually and physically.

Pass-thru hot and cold holding cabinets allow food to be restocked from the kitchen and pulled out as needed on the serving side. Photo courtesy of Matt Andrus, TBCI Design

Saving Labor

Morgan’s walk-up window approach saves on labor hours compared to, say, a scatter station or straight-line layout.

“In traditional school servery models, you’ve got someone on hot food, someone on cold, someone working the register, and a backup person supplying those lines—at least four people required per line,” Hammersley says. “With the walk-up window model, each station requires only one cashier who will also be assembling orders. Two runners—one for hot food, one for cold—handle restocking of all the bays.”

Morgan’s support kitchen, covering 3,640 square feet, includes a prep aisle (floor mixer, sink and slicer and a line of worktables), a hot-prep aisle with eight double-stacked convection ovens, and a third aisle with a range, tilt skillet and worktables facing a three-compartment sink.

Because Morgan, like many HCPS outlets, uses disposable servingware rather than reusables, planners could skip the expense of a dishroom in favor of well-sized storage space for paper and plastic products.

But on the matter of walk-ins, planners aimed high. “During COVID, Hillsborough County schools faced shortages due to unreliable deliveries,” Hammersley says. “So for Morgan, they wanted as much cold storage space as they could get.” This translated into a 725-square-foot walk-in cooler/freezer with nine-foot-high ceilings. The shelving is five tiers high, with ample space for airflow above.

Training Students

Morgan’s well-equipped culinary lab will train future food professionals. Photo Courtesy of Frank Sepcic, PBK Architects

The culinary lab, about 2,000 square feet, offers state-of-the-art foodservice training for Morgan students. “We showcased the lab with lots of glass walls in hopes that kids looking in might be inspired to be a part of the program,” Sepcic says. The lab holds most of the equipment used in restaurants. The lineup includes a charbroiler, a combi oven, six-burner ranges and griddle, ovens and a proofer. “The kitchen will teach students to cook virtually anything a medium- to high-end restaurant could do,” says Morgan culinary instructor Katrina Hollingshed.

The lab includes two workstations and plenty of workspace. Video monitors and a camera positioned on one of the hoods helps keep all students tuned in during cooking demos.

Looking ahead, “In the next year, we expect to have culinary students work in the cafeteria to earn customer service hours they need to graduate,” Hollingshed adds. “They’ll work both the service bays and the back-of-house.”

FACTS

Aquilla J. Morgan High School

Wimauma, Fla.

OPENED: August 2025

MAXIMUM ENROLLMENT: 3,500 students

TOTAL COST TO BUILD: $178 million

SEATING: 1,140 seats

SERVERY & DINING: 14,767 square feet

BACK-OF-HOUSE: 3,640 square feet

MORGAN HIGH SCHOOL: Shani Hall, student nutrition services general manager

CONSULTANT: David B. Hammersley, principal; Ashley Walogorsky, VP of design, TBCI Design, St. Petersburg, Fla.

ARCHITECT: Frank Sepcic, principal and client executive, PBK Architects, St. Petersburg, Fla.

DEALER: Johnson-Lancaster & Associates, Clearwater, Fla.

WEBSITE: hillsboroughschools.org/o/morgan

Key Equipment

SERVING BAYS

LTI counters, food shields, drop-in hot/cold/frozen wells

Structural Concepts display merchandisers

True cold prep tables, roll-thru refrigerators, roll-thru heated cabinets

Hatco hot display cases

Master-Bilt display freezers

Mars air curtain (for outside-facing bay)

Kitchen

CaptiveAire hood

Vulcan range, tilt skillet, convection ovens

SPG universal pan racks

Hobart food slicer, 30-qt. mixer

Bizerba equipment stand

Manitowoc ice cuber, ice bin

3M Purification water filtration system

American Panel walk-in cooler, walk-in freezer

Advance Tabco floor trough, three-comp. sink, worktables, hand sink, shelving

T&S Brass wall-mount faucet, prerinse assembly

Culinary Lab

True reach-in refrigerator, freezer

T&S Brass prerinse faucets

CaptiveAire hoods

Alto-Shaam combi oven, reverse osmosis system

Vulcan six-burner ranges, salamander broiler, griddles, charbroiler

Continental refrigerated stand

Moffat convection oven, proofer

Mars air curtain

American Panel walk-in cooler, freezer

Editor‘s note: Floor plan doesn‘t show the culinary lab.

T&S Brass is pleased to sponsor FER’s Kitchen Design feature. To learn more, visit tsbrass.com.

ABOUT THE AUTHOR

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -