Connecting the Dots: A Look at Connected Kitchen Solutions

From food waste to prep prioritization, connected kitchen products align to chip away at efficiency goals.

When it comes to being on the same page in a kitchen, paper checklists once reigned supreme. But, as third-party kitchen connectivity providers continue to innovate, operators have the chance to do the same—in some cases, regardless of the age or make of their equipment.

Today, a host of tech-savvy solutions can automate, analyze and ease several back-of-house tasks, tackling efficiency hiccups—both in equipment performance and in terms of labor—and putting money back in operators’ pockets. But, ironically enough, you’re probably going to want a checklist to ensure you find the right fit.

Here’s what connectivity providers suggest:

STEP 1: DEFINE YOUR GOAL

While tech providers can help navigate numerous challenges, a mutual understanding of the desired destination marks an excellent starting point, several providers suggest.

For example, are you interested in cutting down on food waste and/or too-high inventory costs? Are you looking to help employees accurately prioritize food prep, in turn improving food quality? Do you need help tracking HACCP data? Or, do you want to save energy?

Automated kitchen timers and oil monitoring can add intuition to operations. Courtesy of Kitchen Brains.

“If there is a clearly defined problem, I guarantee you there is a clear solution with modern technology,” one provider assures.

In the food waste realm, several options exist. One newer industry solution analyzes historical sales data as well as real-time factors like weather, using artificial intelligence to forecast and prioritize demand. “You can define per ingredient what your prep method shall be, whether you want to prep once every three days to save on labor, or you want maximum freshness and absolute zero wastage,” the provider explains. “You can say ‘I want to do 70% of my prep in the morning, and then I’m going to do 30% after the lunch rush.’”

To further ensure prep stays on track, this company offers vision AI sensors able to watch select equipment, like a makeline, monitoring real-time ingredient fill levels and alerting staff via tablet of top priorities—for example, chicken that needs to go on the grill 20 minutes before the pan of chicken runs out. And once sensors at the grill see the chicken hit the grill, the task is automatically bumped, sparing cooks from degloving to interact with a touch screen. Another similarly minded forecasting-and-prep solution reads the appliance controls, then automatically activates a cooking timer on the tablet.

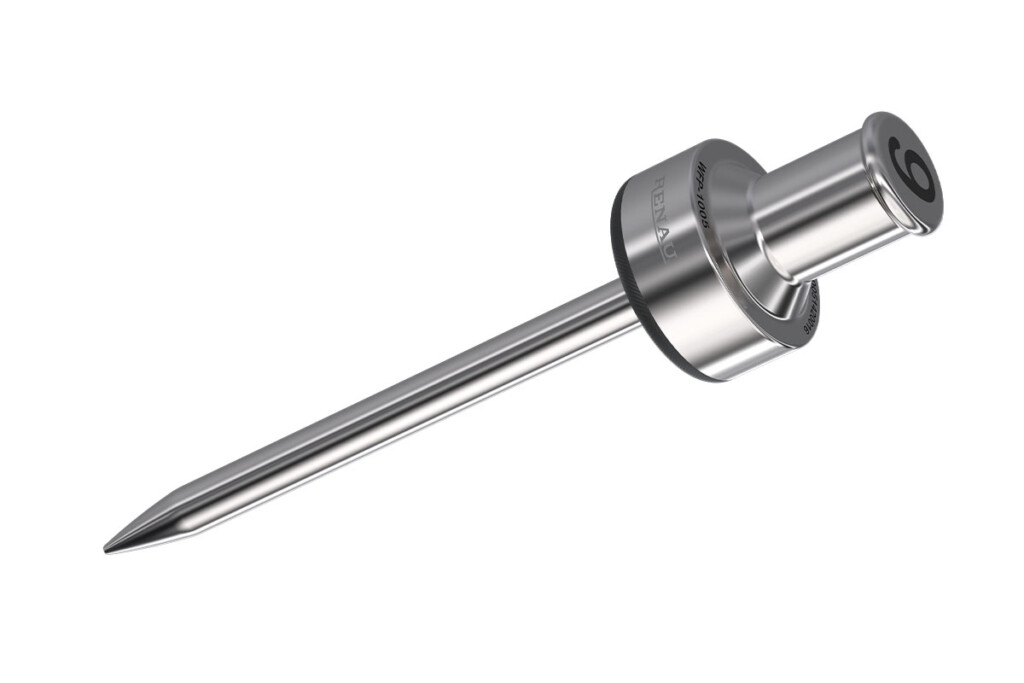

A wireless, self-charging probe marks a new addition on one connected kitchen platform. Courtesy of Renau.

Also helping with food quality and cooking consistency is a self-charging, wireless food probe—a new addition, officially releasing at The NAFEM Show, that, when inserted into food, reports internal and ambient temperatures to a cloud-connected platform. Beyond recording that data, the platform also can guide staff through prep, streamlining LTO rollouts and/or aiding in training. “Those who don’t really have much cooking experience all of a sudden have the ability to perform complex recipes with minimal training,” they say. The same platform also offers cooking timers.

Another function offered by some providers is sensor-driven temperature monitoring of equipment—from hot holding cabinets to walk-ins—to sidestep costly product loss. One of these providers recently launched tracking codes for waste that help corporate see trends and take actions to improve sustainability.

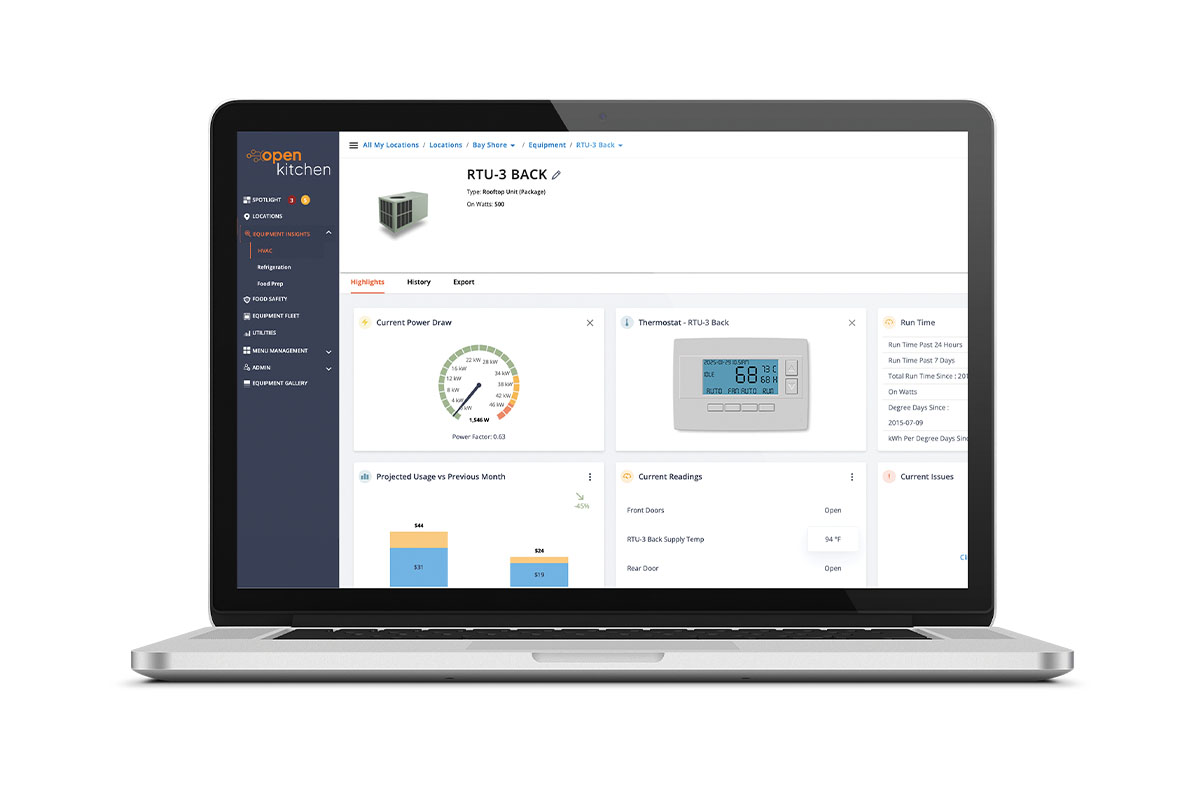

In the energy-monitoring realm, one provider offers internet-connected thermostats and temperature sensors (placed in the ductwork) that let users monitor and control HVAC use across a chain’s portfolio. The same solution also can help diagnose maintenance needs, depending on data from the two components.

No matter your goal, be sure you have a clear vision of the end goal. “Connectivity is great, but at the end of the day, unless you have that data and make sense of it, you don’t get much value out of it,” says one provider.

NOW, WHO IS INVOLVED?

Consider who you want to have access to, and training on, your connected kitchen solution. Courtesy of Powerhouse Dynamics.

Your implementation team might consist of a sustainability manager, head of culinary, or facilities or operations team members. At least one company also offers a proof of value process to kick things off, helping train those involved with the tech. “They’ll have a very good understanding of the technology that they’re investing in, and we will collectively understand ‘here’s how we should set the system up for the way in which you operate,’” they say. “It’s all about making sure you lean in and give enough bandwidth during the proof of value to truly help define what a successful enterprise deployment looks like.”

NEXT STEPS

Some other top-of-mind considerations include:

Proper infrastructure. One company says infrastructure is the most-overlooked component of adding back-of-house connectivity—and a critical one at that. Without it, equipment will show as offline, cutting out valuable data. For those who don’t have this, at least one company offers a secure access point. With another cloud-based solution, enterprise-level Wi-Fi marks a must.

The price of knowledge. Building your own tech stack—or buying all connected equipment, then interacting with different dashboards—can prove quite costly and complex; by comparison, providers we spoke to charge monthly or annual software subscription fees. Some companies also offer or provide tablets, while other software can be accessed via various mobile platforms. When it comes to sensors, at least one provider notes they don’t charge extra if a unit’s layout calls for added coverage—like, say, a makeline running around a corner; rather, the set price blankets the entire brand. Several providers also offer optional ongoing software management services for those without the bandwidth to review internally.

AT LAST

The SaaS space is busy, and constantly evolving, but not all providers are laser-focused on restaurants. When sizing up your options, consider the provider’s track record in the space, and ask about any software limitations. In most cases, integration and reporting will require ongoing collaboration, so you’ll want to pick a partner with whom you’re comfortable.

Tackling Tons

Food waste—one of several issues being targeted by connected kitchen solutions— is a big, multifaceted issue that’s costing operators.

In 2023, 17.2 million tons of food (valued at $175.7 billion) went unsold and uneaten at consumer-facing foodservice businesses, with full-service restaurants wasting the largest share (5.8 million tons) in 2023. Angel Veza, director of innovation at the nonprofit ReFED, shared this data as well as some potential solutions at FER’s MUFES 2025.

Demand planning tools—which Veza likened to “a magic crystal ball”—are one option that she says could help alleviate overproduction, as are smart sensors.

“Not everyone wants a large tech stack,” Veza says. “You start adding all these different technologies, and it gets too complicated, and some just need a drop-in solution; that’s where smart sensors could play a role, with regard specifically to food waste reduction. The biggest opportunity we’ve seen so far is really around monitoring temperature and making sure there aren’t any significant temperature fluctuations that could cause food to spoil or go bad too soon.”

Level Up

GAIN NEW PERSPECTIVE, INSIGHTS WITH SELECT PROVIDERS’ CONNECTED KITCHEN SOLUTIONS.

Powerhouse Dynamics

MODEL: Open Kitchen

DETAILS: Automate and monitor HVAC equipment and energy use, and connect other key equipment on this OEM-agnostic IoT platform. Add visibility with equipment performance notifications. Distribute menus to ovens, fryers and other equipment, and track and record HACCP data. Open Kitchen is PCI certified to ensure data security.

WEBSITE: powerhousedynamics.com

PreciTaste

MODEL: Station Assistant

DETAILS: Remove blind spots with this vision AI solution that captures real-time makeline capacities. Staff is alerted when ingredient prep needs to occur, smart-sizing production and, in turn, reducing food waste. Vision sensors also can be added near a grill or oven to monitor cooking.

WEBSITE: precitaste.com

Kitchen Brains

MODEL: KorrectProduction

DETAILS: By integrating with your POS, this system analyzes historical data to help predict sales and demand. Day-to-day, leverage the knowledge to keep food availability and quality up to speed, and review longer-term chain-wide production on a larger scale. The platform’s kitchen timers also track cooking and holding cycles.

WEBSITE: kitchenbrains.com

Renau

MODEL: Smart Kitchen System

DETAILS: Train staff on equipment operations, recipes and daily tasks via this customizable, multilingual software, displayed via touch screen. A self-charging, wireless probe (the WFP-1005) marks the system’s newest accessory. Use the probe to track internal food temperatures as well as ambient equipment temperature, ensuring product consistency and quality.

WEBSITE: renau.com

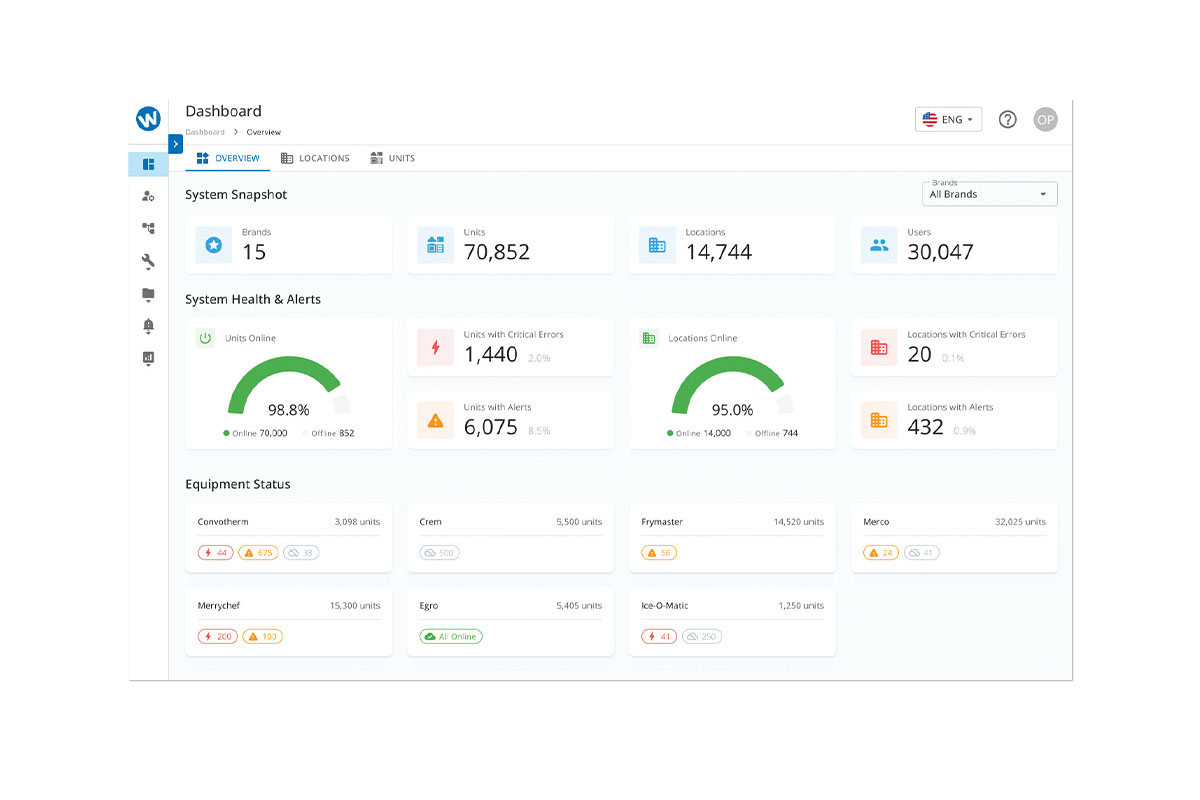

Welbilt KitchenConnect

FEATURE: KitchenConnect

DETAILS: Unite data from connectivity-ready equipment—both from Welbilt brands and other select makers. Enhance cooking processes, run limited-time menus, keep equipment software up-to-date, and track production and operations.

WEBSITE: welbiltkitchenconnect.com

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -