From Heating Elements To Control Panels

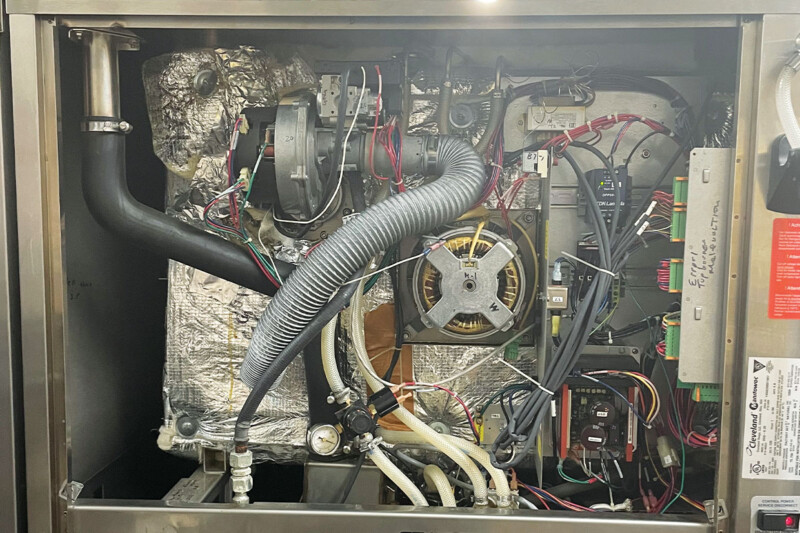

Cecil Blake, of Authorized Commercial Equipment Service, dissects a truck stop's 15-year-old fryer to get it back in working order.

Cecil Blake, a service technician for Authorized Commercial Equipment Service, based in Charlotte, N.C., wasn’t surprised when he got a call asking for help with a fryer having recovery issues. The operator at the truck stop had gotten 15 years of service from the fryer, and Blake knows constant service in a fast-food environment normally leads to some wear and tear on the equipment.

“When I ran the diagnostic test, each element was only registering two amps instead of the required three,” Blake says. Solving the problem required a relatively routine repair job of replacing the three heating elements. After the work was complete, Blake tested the equipment to make sure everything was working properly, only to find the middle element wasn’t coming on at all, and the control panel now showed the “help” error code.

“That error lets you know either the drain switch or the high limit switch has gone bad, and keeps the element from firing up,” Blake says. “I didn’t want to tell the operator we would have to come back the next day with another part to fix the fryer, so I decided to do a little investigating.”

Blake took off the back panel to check the two switches physically. Both were in working order, but he still got the error code upon startup. “At that point I figured something must be wrong with the interface board,” Blake says. “There’s a circuit in the control panel that posts the error code if the high limit switch is open.”

Upon taking the interface board off, Blake saw that the back of it was coated with dried grease. “Sometimes staff has the tendency to overfill the fryer vats, and the grease will seep down into the control panel,” Blake says. The grease had caked up around the plugs in the circuit, preventing the circuit from closing. That meant the error code was showing on the front panel even though the switch itself was closed.

Blake cleaned the plugs, opening the circuit back up, and the error code went away. By physically checking the high limit switch rather than automatically replacing it, he saved the operator time and money by avoiding a replacement part and a second service call.

THE TAKEAWAY

Pay attention to fill levels in fryer vats, and make sure to practice proper cleaning procedures on a daily basis. Grease can cause a multitude of problems in a kitchen, from clogging up circuits and fans to starting fires, making regular cleaning routines important in and around equipment like fryers.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -