Let These Sink Maintenance Tips Sink In

Stay out of proverbial hot water with two technicians' advice for back-of-house sinks.

It’s no dirty secret that adequate sanitation is necessary for any up-to-code operation— and properly working sinks are crucial to that cleanliness.

And yet, from powered sinks to compartment sinks to hand sinks, mishaps can and do happen. Thankfully, the list of sink-related maintenance issues is relatively short, says Smart Care’s Steve Pfaehler, senior technical trainer and a CFESA master technician.

Here are some ways operators can protect their assorted back-of-house sinks:

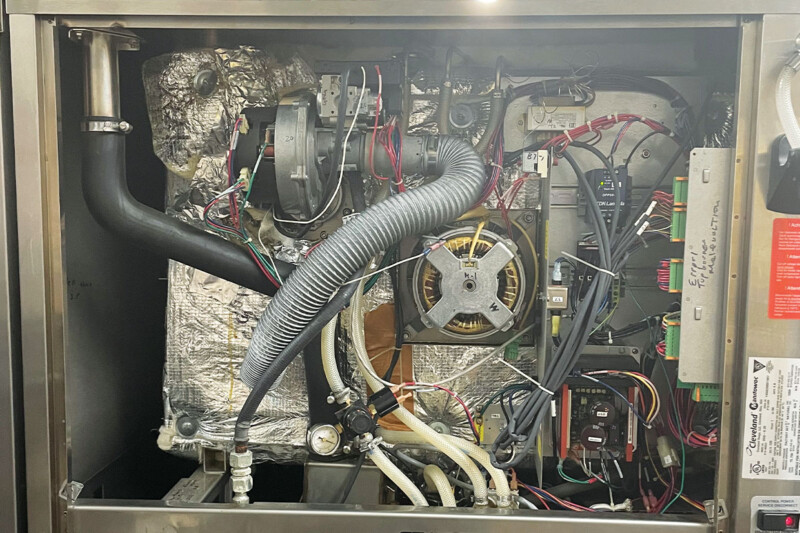

PUT DOWN THE POWER WASHER. Never power wash the outside of your powered sink, urges Pfaehler, as its control compartment “is water-resistant—but not waterproof.” Once water infiltrates the compartment, a new controller and associated parts are the likely fix. Another mistake with powered sinks is running the unit without the proper guards in place, which can allow utensils to reach and damage the motor, Pfaehler says. In a best-case scenario, that mistake will call for a new impeller. At worst? You’ll need a new pump and motor. “Powered sinks are the most costly to repair and can run from a few hundred dollars to a few thousand depending on what broke,” Pfaehler says.

CREATE A BARRIER. Moving to compartment and hand sinks, Pfaehler says carts and/or caddies are a common enemy. “Compartment sinks can be damaged by users pushing carts and caddies under the sink, or using this area as storage, causing damage to the drains and possibly even the sink compartment itself in the form of cracks in the metal,” he says. Hand sinks, if accidentally struck by a cart, may become detached from the wall. While the causes and fixes are pretty obvious in these instances, Pfaehler says an alternate storage area and/or strategic placement of a garbage can next to the sink (to create a barrier) can help sidestep these issues.

TAKE THE TIME TO DO A WALK-THROUGH. As is the case with most pieces of equipment, routine inspections can go a long way. For sinks, regularly check components like faucets, handles, hoses, drains and guards, depending on the specifics of your unit. “In our industry, usually the managers are really busy with the prep in the morning, and they don’t do a walk-through of the whole restaurant,” says J.C. Viteri, a certified master plumber who serves as Tech24’s director of sales for the mid-Atlantic region. “So that’s when you have those calls … [saying] ‘I have an emergency,’ and that can cost.” With routine checks in place, those repairs are less likely to come as a surprise, and will likely carry a smaller cost, too.

ENSURE YOUR EMPLOYEES ARE INVESTED, TOO. Viteri notes that cross connection issues, which leave operators without hot water, can be pretty quickly diagnosed and, ultimately, sidestepped by having check valves and training employees to not leave faucet valves open. Viteri further urges operators to ensure staff members are scraping down plates before those dirty dishes head to warewashing, as accumulated grease, among other particles, can slowly but surely clog drains.

Little by little, each ounce of effort operators put into maintaining their sinks can make a difference. Heed these technicians’ pieces of advice, and follow any manufacturer-specific recommendations (like, say which dish soap to use with a powered sink) to keep your sinks running as needed.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -