The Musts of Ventilation Maintenance

Keep CKV maintenance high on your list of priorities to dodge downtime, parts failures and hazards.

Commercial kitchen ventilation systems are the unsung heroes of the kitchen. The exhaust hood, makeup air system and HVAC unit all work together to keep the kitchen environment comfortable by removing grease, smoke and heat from the atmosphere. However, pulling out all the grease and particulates from the air can lead to clogged filters and ducts, especially when regular maintenance and cleaning fall by the wayside.

To keep priorities in order, here’s what ventilation manufacturers recommend:

Understand the consequences. Knowing what can happen if upkeep on CKV systems is neglected may help operators make planned maintenance a priority. A sign of clogged filters or a full grease trap show as a smoky kitchen or grease dripping from areas of the exhaust hood. Left unattended, the buildup can lead to more dire consequences, such as a kitchen fire. One manufacturer also suggests operators keep an eye on makeup air units or fans on the roof. If left unattended, an overabundance of grease leaking out can damage roofing materials, which could lead to leaks.

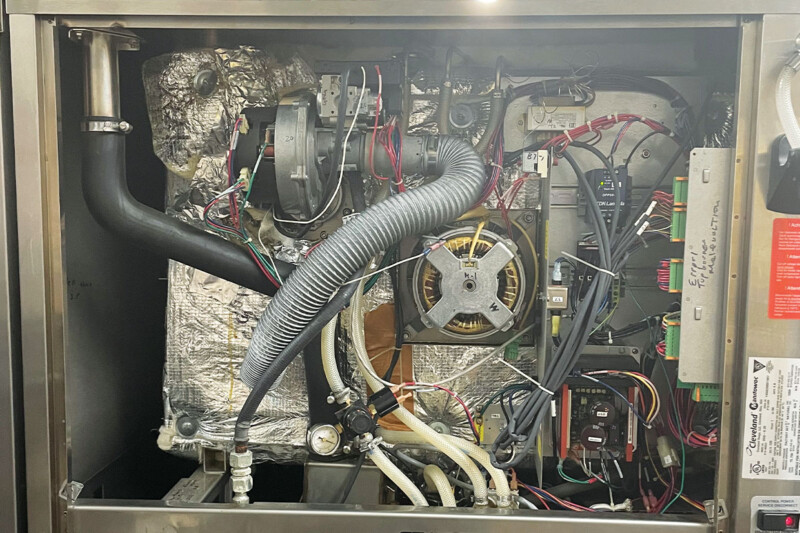

And then there’s the risk of downtime for the kitchen. Grease buildup on fans, motors and bearings can cause parts to fail. Since the components of a CKV system work together, the whole system can shut down if one part fails.

Keep it clean. Maintenance for exhaust hoods consists of three tasks: Clean the filters, empty the grease trap and wipe down the hood. How often you put the filter or cartridge into the dishwasher depends on the volume and type of food cooked under the hood. Most manufacturers recommend starting out with cleaning the filter once a week, and use that to gauge whether it should be cleaned more often. If it takes two or three runs through the dishwasher to get the filter clean, it may be time to up the frequency. Also, regularly replace filters on makeup air units, and wipe grease off the fans and other parts to eliminate buildup.

Don’t forget the ductwork. While many cleaning tasks can be done by staff, a professional should clean the ductwork; how often they come depends on your volume. Manufacturers we talked with noted that operators should be aware of local regulations as well since authorities have strict guidelines for foodservice operations to follow, as grease is such a fire hazard.

Note these ease-of-use features. Some makers offer exhaust hoods with clean-in-place solutions to reduce labor needs. Nozzles inside the hood spray hot water to wash off the back of the filter. While this ensures the filter is cleaned regularly, it is important to remember the rest of the hood still needs to be wiped down manually. One manufacturer designed its hood to curve out over the cooking space. This design makes it easy for operators to reach up and remove the filter for cleaning, rather than having to wait for the range or griddle to cool off before reaching over it to access the filter.

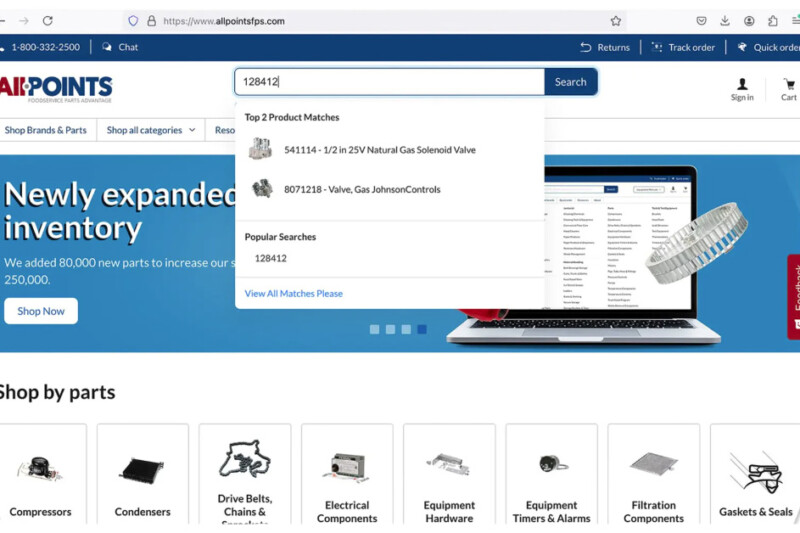

Make use of your resources. The No. 1 recommendation from manufacturers for CKV maintenance is to read and follow all suggested maintenance tasks outlined in the technical manuals provided at installation. You also can find virtual assistance through YouTube videos created by manufacturers, and some equipment now comes with a QR code that will take you to a website for troubleshooting certain error codes. One manufacturer offers certified ventilation training through field sales reps.

Avoid potential downtime by setting up a regular CKV maintenance plan. Taking care of your units will help keep them fully functional through their life and avoid premature breakdowns of components or parts.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -