TECH TIPS: Fryer Care Basics

High-efficiency fryers equipped with built-in filtration and self-diagnostics reduce the amount of work it takes to get optimal performance and long life from your fryer compared with more labor-intensive, basic no-frills fryers. No matter what system you have, however, several golden rules apply; teach your employees, then monitor them to ensure they follow through.

Use Only Approved Cleaning Materials

When it’s time to empty and clean fryer vats, the processes are very important to “follow to a T.” (Manufacturers and cleaning-solution companies post great step-by step cleaning procedures on YouTube.) Shortcuts can cause trouble.

Don’t let your employees use metal spatulas to scrape fryer debris off of the sides. Don’t let them grab any old scouring pad, grill brush or steel wool because it’s convenient; these items can scratch stainless.

“I see this happen a lot, and pretty soon the steel starts pitting and before you know it, you get oil leaks,” says Corby Stow, CFSP, Director-Sales, Oil Solutions Group, Colleyville, Texas. If you routinely see oil or grease buildup in one area of the fryer despite repeated cleaning, you might have a leak. Small leaks always become bigger leaks if left unattended, resulting in lost efficiency, costly repairs or even the need to replace the fryer.

Manufacturers furnish proper long-handled brushes as well as narrow bristle brushes for getting between burners.

Aside from the cleaning process—a boil-out that uses water and a cleaning agent—water and oil are still archenemies. During normal operation, keep moisture away from the fryer; use a dry cloth to wipe down surfaces. Similarly, ban soaps and degreasers when you’re wiping down the fryer because they leave residues behind that cause chemical reactions and contaminate food flavors.

Filter Several Times Daily

When and how many times you filter will be determined by the type, quantity and frequency of the product you cook and, frankly, the quality of the fryer you purchase.

Heavily floured and breaded foods release more crumbs into oil than if you only are frying French fries. But if your fryer is in constant use, even for just one food item, crumbs and food particles break off quickly and carbonize, ultimately degrading the oil.

With hot-oil-resistant gloves, apron and goggles and the proper tool, employees should skim crumbs off of the top of the oil to prevent them from sinking in the vat where they can clog tubes or coils.

Clearing debris from the bottom of the vat requires regular filtering, a manual or automatic process depending on the fryer you purchase.

“It’s very important to understand how to filter and understand the interval for filtration,” says a technical training supervisor for a fryer manufacturer. “And at the end of the night, everyone needs to do a more thorough filtration. Brush and wipe down the side walls of the fryer, make sure there are no crumbs, make sure the temperature probe is clean and heating elements and burner tubes are clean so they can fire properly.”

Train employees to wipe gently around the high-limit and temperature probes, too; they are delicate sensors and can be damaged with rough use.

Pressure fryers often are used to cook heavily breaded items, which shed crumbs; as a result, oil can degrade very quickly. Because the pressure retains food’s moisture, oil is more susceptible to moisture infiltration. Expect to filter oil in this type of fryer every four to six cooking cycles.

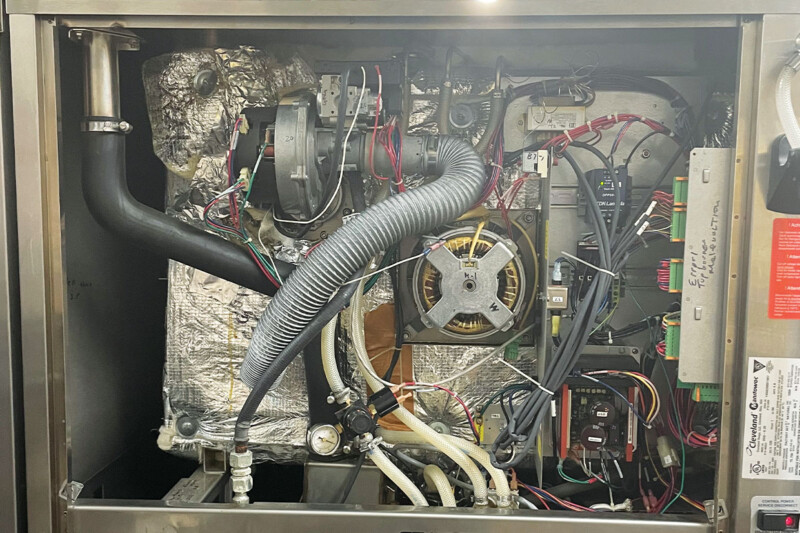

Get The Parts Right

Wrong or poorly functioning parts will derail the whole unit. There’s no room for improvisation when it comes to using the parts that are made for the fryer, from baskets to fryer filters to replacement parts.

John Schwindt, V.P./G.M. of Hawkins Commercial Appliance Service, Englewood, Colo., says operators sometimes choose the cheapest parts, which don’t always fit properly.

It is essential to assemble filter-pan components correctly; sometimes employees take liberties with the filter paper. They insert paper that doesn’t fit the pan, then debris sneaks around the paper, gets into places it shouldn’t and clogs the machine. “I have seen pretty much anything used in place of proper filter paper: aprons, nylons, towels. My favorite was a T-shirt wrapped around a bunch of chicken wire,” he says.

A certified Commercial Food Equipment Service Association technician should inspect your fryers at least once a year to check gas pressures, time melt cycles, calibrate temperatures and adjust other fi ne points—especially for pressure fryers that have more controls than open fryers.

Do Not Top Off

Just like at the gas station, obey the fill-line levels indicated for hot and cold oil. It’s tempting to add a little extra oil to vats at the start of the shift knowing you will lose oil as the day goes on. This causes more trouble than it’s worth, according to technicians.

Oil expands about an inch in a fry pot when it goes from cold to hot. If it overflows, it creates a mess as well as a safety hazard. From a quality perspective, too much oil might not reach proper frying temperatures and won’t fry the food well. Instead, replenish oil as needed when the level dips below the fill line.

Put Baskets In Their Place

Some fry cooks are careless about how they load or season products—over the oil is not good as it causes the oil to break down faster—or they put baskets on top of the fryer flue, the edge of the fryer or other places they don’t belong.

“I see some people take the basket out of the oil and bang it on the back of the fryer to get the oil off. This breaks the basket and the fryer,” says Chuck Eiwen, President of Daubers Inc., a service agency in Springfield, Va.

Baskets only should be placed in two places: in the oil or on a basket hanger over the oil. Put them anywhere else and oil drips and dribbles into fryer parts that can’t be reached or cleaned easily, gumming components and creating a fire hazard.

Keep Air And Light Out

Not frying for a few hours? Protect the oil from degrading unnecessarily by turning the fryer off or reducing the temperature to about 230°F-280°F and covering the vats.

Some high-efficiency machines automatically go into an idle phase if nothing is submerged for a while.

Covering the oil vat blocks airborne particles from contaminating the oil, even from miniscule dust motes, airborne flour and more. Stow notes two other threats to uncovered oil: Air speeds the oxidation process that breaks down oil. Also, if a cleaning crew power washes the floor, debris can fly into open vats.

Recognize Bad Signs

There are obvious signs that something is wrong with your fryer; don’t just keep on frying—address them.

Oil that’s smoking, bubbling or foaming indicates too much heat or moisture. Check the thermostat and filter the oil. Oil that’s an orange-copper color is contaminated and indicates filtering is overdue. A variation in the cooking times for the same food items probably means the oil temperature is not what the temperature dial shows. Verify the oil temperature with an external thermometer.

A loud sound when you’re filtering might mean there is too much air in the oil return lines that are used during filtration and o-rings, which make the line connections airtight, need to be replaced. A popping or shotgun sound when the fryer is igniting signals that the burners are clogged; it’s imperative to clean them or the gas can’t distribute and ignite. And if electronic error codes keep displaying on the control panel, stop frying and figure out why.

If your employees aren’t trained in fryer maintenance, your fryers won’t be maintained. Manufacturers offer a range of training materials, videos, equipment quizzes and instruction cards and diagrams that can mount inside of the fryer doors—all help reinforce employee knowledge.

“High employee turnover means that information has to be taught over and over on an ongoing basis, and you need to have some sort of regimented training procedure,” one technician says.

He advises a “What’s in it for me?” training approach to make employees care about fryer maintenance. Telling them stories of past preventable fryer disasters or describing the clean up and care they’ll have to do if they don’t treat the fryer right usually will do the trick.

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -