An Inside Look at Ice Machine Advancements

Is your ice machine keeping up? For added equipment reliability and performance, consider aid from newer equipment features.

From filling ice baths and blanching foods to keeping drinks cool for customers, ice plays an important role in every foodservice operation. Any downtime means you’re left scrambling to purchase bags of ice to keep the kitchen running, costing time and money.

In a perfect world, ice machines would only be installed in conditions where air temperatures are 70°F at all times, water is filtered and comes in at 50°F, and airborne pollutants are nonexistent. But in reality, ice machines are often placed in hot kitchens where yeast and bacteria float through the air, and water contains minerals such as calcium and lime. These factors can lead to scale buildup and mold in water lines and other areas, and dirty air filters—all of which can cause machines to operate inefficiently and eventually cause undue wear and tear on parts.

To improve the lifespan of your ice machine and keep downtime at a minimum, manufacturers recommend regular cleaning and scheduled maintenance by service technicians. In conjunction, manufacturers also have sought to simplify upkeep for operators. Here’s how:

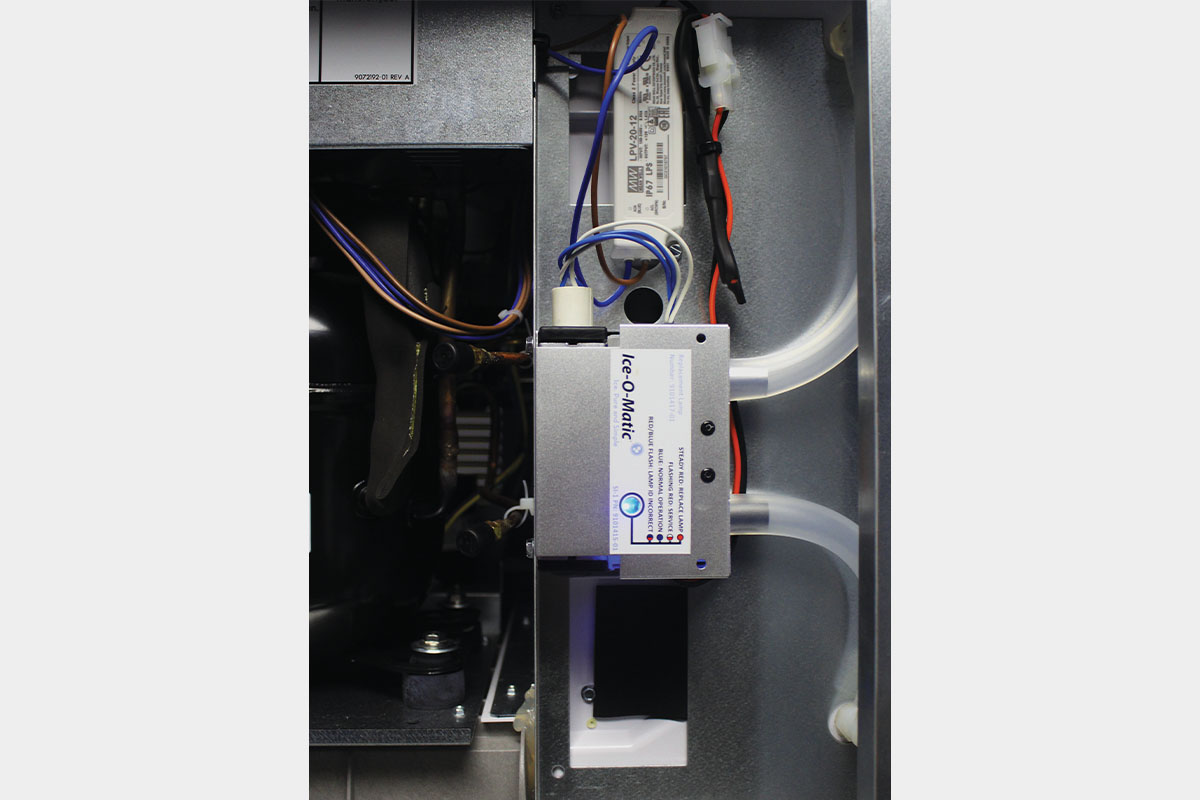

Cleaning the food zone marks an important part of ice machine maintenance. Courtesy of Ice-O-Matic.

Easy-to-clean and maintain machines. Rounded edges and corners make wiping out the ice bin easy. Some manufacturers have extended that ease of cleaning to the food zone as well, creating components that can be removed without tools to run through a dishmachine. Eliminating the need for tools not only makes it simpler for operators to take out the parts, it also ensures dirty tools aren’t used to put clean components back in the food zone. Manufacturers also have found ways to make repair and maintenance easier, from putting the control panel on the front of the machine where it’s easier to access, to being able to replace the air filter without having to take the panel off.

User-friendly cleaning. Keeping the tubes and water lines clean is just as important as sanitizing the food zone and ice bin. A couple of manufacturers have a feature that completely purges the water in the machine on a regular basis, helping ensure the water used to make ice is free of contaminants. Some ice machines do this on a regularly timed cycle, while one maker has a sensor that measures water quality and automatically adjusts the frequency of the flush cycle. Running the sanitization and deliming cycles also is important. Within the last few years, makers have implemented touch screen interfaces that provide step-by-step instructions on cleaning. Some even have one-touch cleaning cycles that can run with ice still in the bin.

Bacteria-fighting elements. Many ice machines are made with plastic that has been injected with an antimicrobial substance, such as silver ion, that prohibits the growth of bacteria, mold and other microorganisms on surfaces. Ozone devices, sold as an accessory to ice machines, provide a second layer of bacteria defense, using ultraviolet light technology to sanitize air from the food zone. This is an especially important feature for operations baking bread or making pizza dough where yeast is airborne throughout production.

Airtight construction. One of the newest innovations is an ice machine with a fully enclosed evaporator. An insulated evaporator plate and the use of R-290 refrigerant not only allows the machine to quickly freeze water, but also warms up the plate in defrost mode quickly, which eliminates the need for any type of harvest assist. The back of the plate is sealed with antimicrobial plastic to protect the insulation, which in turn keeps out mold spores and reduces the possibility of contamination.

From performance data to maintenance intel, touch screens offer insight, adding ease of use. Courtesy of Manitowoc.

Making the Move to a New Ice Machine

Even with the best maintenance program in place, parts fail and equipment ages. If your machine is still under warranty, or isn’t working due to issues with the water pump, faulty valves or other issues outside of the refrigeration-related components, you would probably consider calling a service technician to get it up and running again. But once the machine is out of warranty, the evaporator and compressor are more costly repairs, enough to consider buying a new machine rather than making the fix.

See the “Repair or Replace” sidebar below to help determine if it’s time to repair or replace your existing unit. Replacing an ice machine provides an opportunity to take advantage of new features, stay up to date with current trends and ensure you’ve got the right size machine for your operation.

When considering what size and type of ice machine to buy, remember ice needs change over time. If your old unit was working hard to keep up with demand, you might look for a bigger machine. Or you might consider replacing one unit with a number of smaller ice machines. For example, a quick-service restaurant might purchase one ice machine for the kitchen and another for the front where customers pour their own drinks. This eliminates the need for employees to dump ice into a bin, which not only frees up time for other tasks but also takes away a possible food contamination mishap. If you’re sticking with the same size, consider keeping your bin and only purchasing a new production unit. This can save money; just be careful that the sizes will align.

Customers’ preferences also change, so in addition to the size and number of machines, getting new equipment allows for a new ice type.

For example, if you’re adding a craft cocktail menu, you might look at ice machines making large cubes, but if soft drinks are a big seller, nugget ice might better suit your needs.

Another advantage to new ice machines is improved efficiencies. Manufacturers are currently modifying and re-engineering their lines of ice machines to be in compliance with certain Environmental Protection Agency regulations that were created to reduce the production and consumption of climate-damaging hydrofluorocarbons. Look for models that use R-290 or R-448, and you’ll be ahead of the curve with meeting the regulations. Plus, ice machines that use R-290 are almost 30% more energy efficient than other models.

From new technologies to more efficient machines, the equipment used to make ice is constantly improving. No matter when you choose to purchase a new machine, you’re sure to have an upgrade that improves operations in your kitchen.

Repair or Replace

While new ice machines offer improved technologies and efficiencies, the biggest factor when it comes to deciding when to replace a unit is cost.

Repair: It’s a good choice if your machine is still under warranty.

Replace: If the repair will cost more than half the cost of a new machine, makers recommend considering replacement. Keep a log of service calls and costs to track spending and help weigh whether it’s time for a new machine.

If your machine is due for an upgrade, it’s a good time to consider changing your size and/or type of ice. Courtesy of Scotsman.

Cool Additions

Manufacturers dial in cleanliness, ease of use and equipment longevity with assorted ice machine features.

Hoshizaki

Feature: EcO3

Details: Once attached to the incoming water line, this system delivers ozone-treated water to kill bacteria, yeast and mold, in turn sanitizing the machine, bin and related parts. The result is reduced downtime and labor for routine maintenance. Replace the electrolytic cartridge every six to 12 months.

Website: hoshizakiamerica.com

Manitowoc

Feature: IndigoNxt easyTouch

Details: An icon-based touch screen menu eases operation, keeping operators in the know on day-to-day system performance, potential machine errors and more. Use the screen to program ice production, saving energy, and keep an eye out for routine maintenance alerts. In the event of an issue, use the touch screen to find local service support as well as diagnostic details that can potentially speed up maintenance.

Website: manitowocice.com

True Mfg.

Feature: NcapsuL8

Details: This fully sealed evaporator, part of TCIM-630 (pictured), along with an insulated evaporator plate, drives faster cycle times and better energy efficiency. The design also improves machine cleanliness, eliminating the possibility of mold or slime growing behind the evaporator plate.

Website: truemfg.com

Scotsman

Feature: XSafe

Details: Keep a bin cleaner for longer, even in hard-to-reach areas, with this optional sanitation system using UV-C light. The automatic, chemical-free device circulates cold oxygen plasma inside the unit to sanitize the air and surfaces alike, keeping ice clear and clean. Retrofit installation is available for owners of modular Scotsman machines.

Website: scotsman-ice.com

Ice-O-Matic

Feature: SafeIce

Details: This automated, chemical-free sanitation system works to reduce yeast, viruses and other microorganisms, enabling operators to reduce equipment cleanings and associated costs. Maintain cleanliness with an annual UV bulb replacement. Specify the system at the time of purchase, or as a field-installed upgrade for CIM machines made in 2021 or later.

Website: iceomatic.com

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -